Intelligent Substation Industrial Ethernet Technology Solution

Release date:

2025-09-28

Source:

Author:

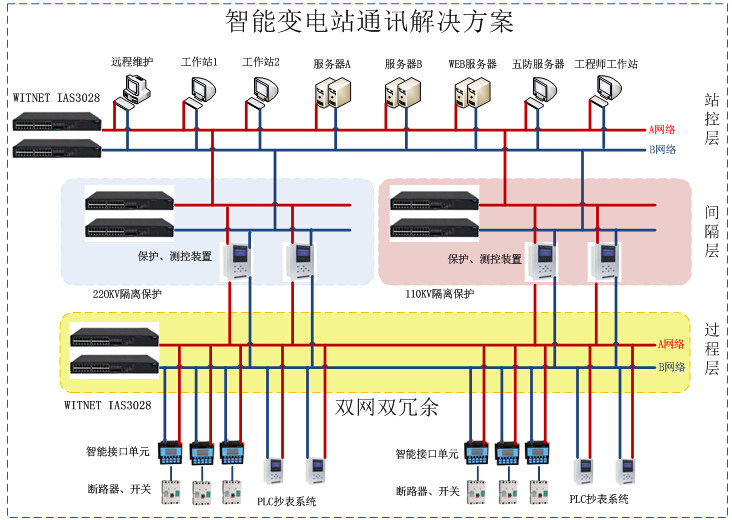

A digital/smart substation is built upon intelligent primary equipment and networked secondary devices, leveraging the IEC61850 communication protocol. The IEC61850 standard divides the substation’s communication architecture into three layers: the process layer, the bay layer, and the station control layer. High-speed network communication is employed both within each layer and between them. The substation’s overall communication network can be further categorized into two key components: the station control layer communication network, which connects the station control layer with the bay layer, and the process layer communication network, linking the bay layer with the process layer. This advanced substation design enables seamless information sharing and interoperability among smart electrical devices, paving the way for a modernized power infrastructure.

Smart Substation Industrial Ethernet Communication Solution

Project Overview

A digital/smart substation is built upon intelligent primary equipment and networked secondary devices, leveraging the IEC61850 communication protocol. The IEC61850 standard divides the substation’s communication architecture into three distinct layers: the process layer, the bay layer, and the station control layer. High-speed network communication is employed both within each layer and between them. The substation’s overall communication network can be further segmented into two key components: the station control layer-to-bay layer communication network, which facilitates interaction between the station control and bay levels, and the bay layer-to-process layer communication network, enabling seamless information exchange among smart electrical devices at the process level. This setup empowers modern substations to achieve advanced information sharing and interoperability among intelligent substation equipment.

A reliable and intelligent communication network is a key factor in the successful operation of substations when transmitting and distributing electricity across large areas.

Due to the unique environment of substations and the requirements of automation systems, the communication network within the substation automation system must feature rapid real-time responsiveness, exceptional reliability, superior electromagnetic compatibility, and robust security.

To address the potential information bottleneck caused by the large number of monitoring sites and vast amounts of data in the intelligent substation automation system, this solution employs high-performance industrial Ethernet switches at the network access layer.

Technical Solution

Due to the continuity and critical importance of power generation, the reliability of the station's communication network is paramount. It’s essential to prevent communication disruptions within the station caused by failures in individual devices or switches. Therefore, for smart substations, it is recommended to use industrial Ethernet switches compliant with the IEC61850 standard to build the station control layer and process layer networks. As demonstrated in this smart substation, the process-level network achieves a converged architecture, integrating three key networks into one: the "GOOSE" network, the SMV network, and the clock synchronization network—all sharing the same infrastructure.

The WITNET IAS3028 industrial Ethernet switch, supporting IEC 61850 through layered deployment, delivers precise synchronization and offers dual-network, dual-redundant connectivity for merging units, intelligent interfaces, and PCL metering system units. The process-level backbone network exclusively uses fiber-optic connections, also configured as a redundant network. In the event of a network link failure, the system automatically recovers quickly, significantly enhancing overall network reliability.

An SNMP-supported WITNET IAS3028 industrial Ethernet switch is installed between the station control layer and the bay level, delivering nanosecond-level synchronization accuracy. It features a dual-network redundancy connection mode to ensure seamless communication and enable real-time monitoring.

Network Topology Diagram

Scheme Advantages

- By implementing a dual-star industrial-grade redundant network, we ensure both the real-time performance and the reliability of data transmission.

- Industrial-grade chips, industrial-grade power modules, and a low-power design ensure the high reliability of the industrial Ethernet switch system.

- Industrial Ethernet switches have passed Level 4 electromagnetic compatibility testing, demonstrating excellent resistance to electromagnetic interference.

- Industrial Ethernet switches are fully interconnected with merging units and intelligent interface units via fiber optics, ensuring zero electromagnetic interference and reliable data communication.

Equipment parameters and functional features

Product Features

Excellent device features & flexible installation options: wide-temperature, dustproof, and moisture-resistant design.

Operating temperature: -40 to 85°C, storage temperature: -45 to 85°C, operating humidity: 0–95% (no condensation); features a fanless heat dissipation design with a metal enclosure, offering IP40-rated or higher protection; customizable for rack, rail, or wall-mount installations.

Operating reliably and stably in harsh electromagnetic environments:

Through industrial-grade electromagnetic compatibility testing, it effectively defends against industrial interference—including high-voltage AC electric fields, electrostatic fields, arcs, and thyristors—as well as natural disturbances like lightning strikes, various forms of electrostatic discharge, and geomagnetic storms.

The equipment boasts an average mean time between failures exceeding 300,000 hours and provides spare parts year-round.

Fast redundancy:

Supports the IEC62439 MRP international standard ring network redundancy protocol, with redundancy protection time less than 20ms, and supports tangent-coupled ring network configurations.

Supports RSTP/STP (IEEE 802.1w/d) redundancy protocols and features advanced loop protection functionality, effectively preventing network-wide storm issues.

Security advantages:

Supports VLAN (Virtual Local Area Network) technology;

VLAN is an essential feature of secure switches. VLANs can span one or more switches, regardless of their physical locations, making devices appear as if they’re communicating within the same network. On a switch, VLANs enable isolation of broadcast domains, effectively dividing the network into independent, discrete areas—and even allowing you to control whether these areas can communicate with each other.

Traffic control function;

Traffic control in switches can prevent abnormal bandwidth overload caused by excessive traffic from broadcast packets, multicast packets, and unicast packets with incorrect destination addresses, while also enhancing the overall system performance and ensuring secure, stable network operations.

Supports port aggregation;

Multiple port aggregation not only increases the bandwidth of the link transmission but also provides redundancy protection for the transmission link, while simultaneously ensuring an even distribution of bandwidth.

IEEE 802.1x authentication mechanism;

The IEEE 802 protocol suite's Local Area Network Access Control Protocol is a port-based access control mechanism. It leverages the advantages of IEEE 802 LANs to provide a robust method for authenticating and authorizing users connecting to the network—effectively allowing legitimate users to gain access while blocking unauthorized ones, thereby safeguarding network security.

QoS mechanism;

Bovia Communications' industrial Ethernet switches utilize the IEEE 802.p QoS CoS/TOS/DSCP prioritization scheme, ensuring real-time and reliable transmission of time-critical data.

Supports broadcast storm suppression and IGMP-Snooping multicast protocol to enhance network transmission efficiency.

System logs;

The switch's logging feature can transmit system errors, configuration details, status changes, periodic status reports, and other information to the log server. Network administrators use this data to monitor the device's operational health, identify potential issues early on, and promptly make necessary configuration adjustments or troubleshoot problems—ensuring the network operates securely and reliably.

Unified network management;

In addition to providing web-based access, it also supports multiple network management methods such as CLI, TELNET, SNMP, and SSH.

Flexible configuration options for power input levels, with dual-power redundancy functionality;