Bovy Energy Efficiency Management System

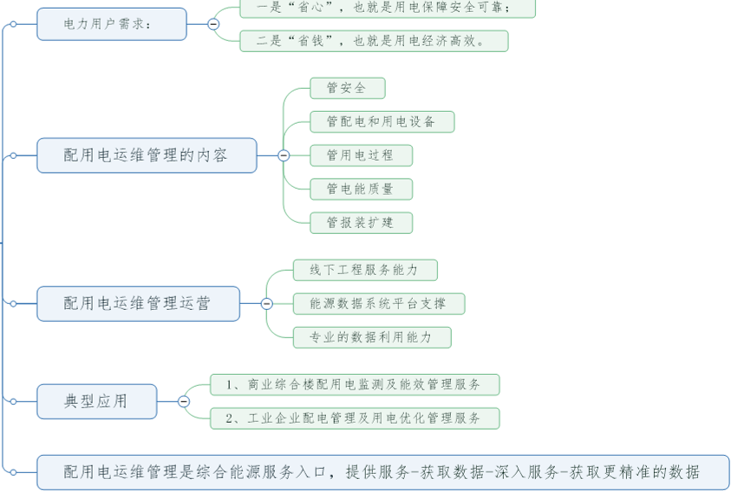

The Bovii Energy Efficiency Management System is designed around an "Source-Grid-Load-Storage-Use-Control" object configuration, making it adaptable to a wide range of energy-related applications across industries. These include online energy monitoring, anomaly diagnosis and analysis (including predictive warnings), energy trading, energy efficiency management (covering consumption analysis, efficiency assessment, and optimized control), intelligent operations & maintenance, and integrated energy service scenarios such as coordinated optimization control among source, grid, load, storage, use, and control systems. The system platform comprises several key modules: a data acquisition module, an equipment management module, a basic management module, a report management module, a business homepage, an online monitoring module, an online alert management module, an intelligent operations & maintenance management module, an operational analysis management module, a safety diagnostics and analysis module, a consumption management module, an energy efficiency management module, an analysis report management module, and an energy dashboard management module. On-site monitoring devices used for data collection include energy gateways, energy efficiency data concentrators, energy efficiency monitoring terminals, smart meters, smart sensors, and their associated communication networks.

Category:

High-Speed Rail Energy Management System

Keywords:

Product accessories:

Email: daimirong@broadwit.com.cn

- Product Description

-

Main station system

The Energy Efficiency Management Master Station System can be applied across a wide range of integrated energy service scenarios, including smart rail transit (trains and subways), smart highways, smart factories, smart industrial parks, smart agriculture, smart fisheries, smart ports, schools, hospitals, commercial complexes, and government institutions. It supports comprehensive functions such as data collection for various energy sources—including water, electricity, natural gas, steam, nitrogen, oxygen, coal, and oil—as well as data storage, cleaning, and processing. The system also enables energy visualization, anomaly detection and predictive alerts, energy trading, consumption analysis, energy efficiency assessment, optimized control, intelligent operations and maintenance, and coordinated optimization control among energy sources, grids, loads, storage, and usage. Additionally, it offers features like fault location, identification of energy consumption bottlenecks, and generation of relevant operational reports. The master station system comprises key components such as a communication server, data acquisition server, database server, application server, web server, cloud platform, mobile app, energy dashboard, and associated network equipment.

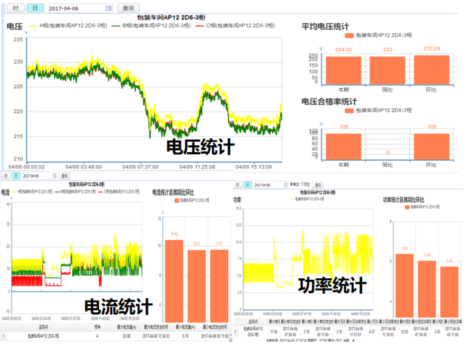

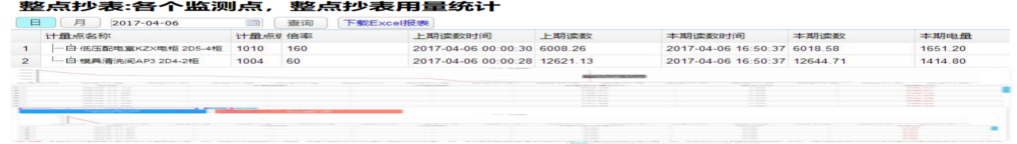

Main Station System – Energy Visualization Management

The energy visualization management system of the energy efficiency management master station includes real-time collection and monitoring of various energy data—such as water, electricity, natural gas, steam, nitrogen, oxygen, coal, and oil—promoting transparency in user energy consumption, enabling timely detection of energy usage anomalies, and helping users minimize energy wastage caused by leaks or inefficiencies.

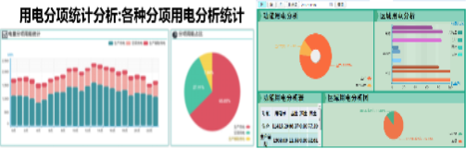

Main Station System - Energy Consumption Analysis

The energy efficiency management master station system’s energy consumption analysis includes hourly meter reading, energy cost allocation management, energy bill settlement, energy trading, user energy usage analysis, energy unit-specific energy consumption analysis, energy consumption quota management, load forecasting, power prediction analysis, energy balance analysis, and energy dashboard management. It also supports period-over-period and year-over-year comparisons, multi-object comparison analysis, benchmarking analysis, and ranking analysis—providing actionable insights to help users optimize energy use in a scientific and efficient manner. This ultimately promotes a balanced supply-demand relationship for energy consumption, enables timely detection of energy anomalies, and helps reduce overall energy costs.

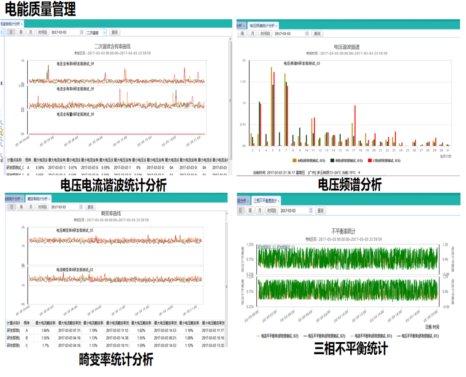

Main Station System – Multidimensional Energy Efficiency Analysis

The multi-dimensional energy efficiency analysis system of the energy management master station includes comprehensive energy efficiency metrics such as overall energy consumption, per capita energy use, energy consumption per unit area, energy intensity per unit output, and energy consumption per 100 kilometers traveled by trains. It also covers economic indicators like energy cost per unit area, energy cost per capita, and energy cost per unit of output. Additionally, ecological metrics are analyzed, including carbon dioxide emissions per unit floor area and per capita CO₂ emissions. The system further provides detailed energy efficiency assessments, such as user-specific and energy-consuming-unit-level analyses, along with equipment, system, station, and line-level energy efficiency diagnostics. Other key components include line loss analysis—covering partitioned, voltage-based, line-specific, and substation-specific breakdowns—as well as theft detection. The platform also supports precise identification of energy consumption issues and quantifies potential energy-saving opportunities. Furthermore, the system conducts energy balance and multi-energy complementary analyses, alongside energy performance evaluations that encompass energy efficiency quota management, benchmarking, and quantitative performance assessments. It also enables energy-saving optimization strategies, including optimized control for individual energy-consuming units, refined energy balance management, targeted electricity usage adjustments at substations, and coordinated optimization across generation, transmission, distribution, storage, and consumption systems. Finally, the system facilitates year-over-year and month-over-month comparisons, multi-object comparison analyses, benchmarking exercises, and ranking evaluations to provide a holistic view of energy performance trends and areas for improvement.

Main Station System - Alarm Monitoring

The energy efficiency management master station system’s alarm monitoring includes anomaly analysis, fault localization, and root cause tracking, enabling proactive identification of equipment and energy pipeline issues for timely resolution. It comprises two key modules: the Safety Diagnosis & Analysis Module, which performs diagnostic assessments of operational safety, fault localization, lifespan evaluations, and health status evaluations, ultimately generating comprehensive safety diagnosis reports to support equipment upgrades and maintenance operations; and the Online Alarm Management Module, which provides a real-time event database interface displaying both live events collected by the data acquisition module and diagnostic events generated by the safety analysis module. This module also offers alert notifications and streamlined alarm handling, seamlessly integrating with intelligent operations to automate end-to-end services such as fault detection, root cause analysis, rapid repair, and smart task assignment—all designed to enhance operational efficiency and reliability.

Main Station System – Intelligent Operations and Maintenance

The intelligent operations and maintenance of the energy efficiency management master station system is an extension of the online alarm management module. It automates the intelligent dispatching process for identified incidents, tracks and reports back the resolution outcomes, builds a library of alarm event handling solutions, and also enables smart dispatching for preventive maintenance. Additionally, it provides advanced remote control capabilities for emergency situations, seamlessly integrating end-to-end services such as fault detection, root cause analysis, rapid repair, and intelligent task assignment—all delivered automatically.

Main Station System – Energy Ecosystem Services

System Advantages

Facing the drawbacks of traditional energy management systems—such as engineering complexity, incomplete data, data logic errors, and high user difficulty—we can leverage PLC technology and ultra-low-power wireless solutions to achieve more flexible data integration, streamlined installation processes, smarter data cleansing, intelligent identification of energy-link topologies, and highly efficient supplementary data collection management. This ensures the completeness, accuracy, and logical consistency of energy data, while also enabling automatic fault localization and analysis, as well as automated identification of energy consumption issues—simplifying system usage significantly. As a result, even non-energy or electrical professionals can easily operate the system with confidence and ease, eliminating the awkward situation of having to hire expensive experts when basic electricians would suffice!

- The system supports multiple communication access modes, including wired Ethernet and RS485 for on-site smart meters, as well as wireless options such as carrier-based (broadband/narrowband), low-power radio, Zigbee, NB-IoT, and 3G/4G connectivity.

- The system supports access via multiple protocols, enabling the platform to seamlessly integrate devices and equipment from various manufacturers—regardless of their specific protocol requirements. By leveraging the rules engine Drools, it allows users to encapsulate and create "custom protocol scripts," facilitating rapid development while providing robust debugging tools and dynamic runtime integration capabilities.

- Implement more rigorous data cleansing, introduce an energy link topology structure and an energy rule model, analyze and assess the reasonableness and accuracy of the collected raw data, flag unreasonable data as unreliable, and re-collect missing or inaccurate data to ensure that the energy data and energy link structure remain consistent with the actual site conditions.

- More efficient data supplementation: Implement a hierarchical, multi-level supplementation mechanism to ensure data integrity and support advanced big data analytics capabilities.

- Users can conveniently check the status of energy, equipment, and systems—without leaving home—through web or app-based interactions.

- Proactive safety diagnostics and analysis, energy efficiency diagnostics and analysis, along with proactive anomaly detection and assessment—enabling automatic alerts and seamless task assignment. This system automatically handles the entire process, from fault identification and root cause analysis to rapid repair and intelligent dispatching of service teams.

- The cloud platform leverages big data mining, fault model identification, and energy consumption anomaly factor analysis to automatically pinpoint fault locations, detect energy-use issues, and quantitatively assess energy-saving potential. It also compares the investment payback periods of energy-saving optimization solutions, provides color-coded alerts for abnormal conditions, and generates automated operational analysis reports—eliminating the need for specialized expertise, making it easy and intuitive for non-professionals to use effectively.

Core Component — Energy Gateway

The Energy Gateway (Smart Gateway) is built on a robust, embedded communication hardware and software platform, offering features such as strong real-time performance and high reliability. It can collect data from various sensing devices—including electricity, water, and gas meters, as well as temperature, humidity, and switch statuses—and perform appropriate processing, storage, and control output functions. This enables seamless data exchange between the energy efficiency management system platform and the collection terminals.

Key Features

Mechanical Grade I, Electromagnetic Compatibility Grade IV CPU: Freescale PowerPC and TI AM335X Memory: NorFlash for program storage; Industrial-grade SLC Flash for historical data logging Enclosure: Plastic/metal housing with grounding feature Environmental Specifications: Supports wide-temperature operation—storage range of -40°C to 85°C, while operating between 25°C and 75°C Supports connectivity for up to 256 serial devices, 128 LoRa devices, and 64 Ethernet devices Equipped with: - 4 RS-485 ports - 2 electrical or optical Ethernet ports - 1 dedicated LoRa interface - 1 integrated 4G module - 6 DI/2 DO/2 AI channels Data Acquisition Protocols: - Supports Modbus RTU, Modbus TCP, DL/T645, CJ/T188, IEC103, IEC104, and AnyPolling (for developing custom, non-standard protocols). Additional acquisition protocols can also be easily expanded. Remote Communication Capabilities: Connects seamlessly to the monitoring platform via 3G/4G networks, fiber optics, or Ethernet, enabling real-time data collection, processing, and storage—while ensuring uploaded data is promptly transmitted to the central control center. Communication Forwarding Protocols: - Modbus TCP (both server and client modes) - Modbus RTU - IEC104 (also available in both server and client configurations)

Q/GDW376.1-2013 "Communication Protocol for Electricity User Energy Information Collection System: Master Station to Collection Terminal Communication Protocol," "Power Demand Side: Master Station to Substation Data Interface Specification," "Ministry of Housing and Urban-Rural Development: Technical Guidelines for Transmission of Itemized Energy Consumption Data in Energy Monitoring Systems for Government Office Buildings and Large Public Structures," "IoT MQTT+JSON Protocol," and the Alibaba IoT Protocol

Core Component – Energy Efficiency Data Collector

The system consists of four key components: a power line carrier communication module, a power supply board, a core board, and a 4G module. It primarily handles the collection, storage, and transmission of electrical parameter data from RS485 meters and carrier-based meters, while also enabling advanced features such as analyzing abnormal meter operating conditions, configuring parameters, and providing intelligent control capabilities. Power line communication leverages existing electrical wiring to facilitate data transfer between meters and collectors, eliminating the need for new wiring installations—making it simple to implement and easy to maintain.

Key Features

- Featuring multi-layered protection against electrical surge impacts and lightning protection measures

- The energy efficiency data concentrator communicates remotely with the main station of the energy efficiency management system, using either a 4G public network or a dedicated fiber-optic/ethernet private network.

- The energy efficiency data concentrator and the energy efficiency collector communicate via Power Line Communication (PLC).

- Various types of data can be collected via the RS485 interface.

- 2-channel RS-485 interface, 1-channel carrier communication, 1-channel infrared, 1-channel 4G, and 1-channel Ethernet

- Real-time data acquisition, processing, and storage, with the collected data uploaded to the central system. It features advanced parameter settings and intelligent control capabilities, including meter event logging, analysis of power supply anomalies in distribution areas, proactive reporting of terminal parameter changes, meter reading failures, and active notifications for terminal power-off/on events.

- The energy efficiency data concentrator complies with the communication protocol standards Q/GDW 1376.1—2013 and its extended protocols when communicating with the master station system. It also supports Q/GDW 1376.2—2013 and the DL/T 645-2007 multi-function electric meter communication protocol for communication with the local communication module.

Core Component – Power Line Communication PLC

Based on IoT power-line communication, this solution leverages local network communication to address the "last few hundred meters" of connectivity for smart devices. It incorporates narrowband power-line carrier communication, a dual-mode approach combining narrowband carrier with 433 MHz wireless technology, and broadband power-line carrier communication. These technologies offer advantages such as strong wall-penetrating capabilities, unobstructed signal transmission, and ease of implementation.

It can communicate with any device connected to a power line via the electrical wiring.

Provides comprehensive technology options for connecting the "last few hundred meters" of the IoT;

Energy efficiency data concentrator with power line carrier communication module, associated detection and measurement circuits, operational switches, and power supply section.

Key Features

- Achieve carrier data transmission between the carrier collector, carrier meter, and energy efficiency data concentrator.

- Supports digital input

- Support for Power Line Communication (Narrowband/HPLC) Upgrade and Maintenance

- Electric meter data collection, including voltage, current, power, energy consumption, and power factor data.

- Industrial-grade design, operating temperature range: -40°C to +85°C

Leave a message for inquiry

If you're interested in our products, please leave your email, and we'll get back to you as soon as possible. Thank you!

More products